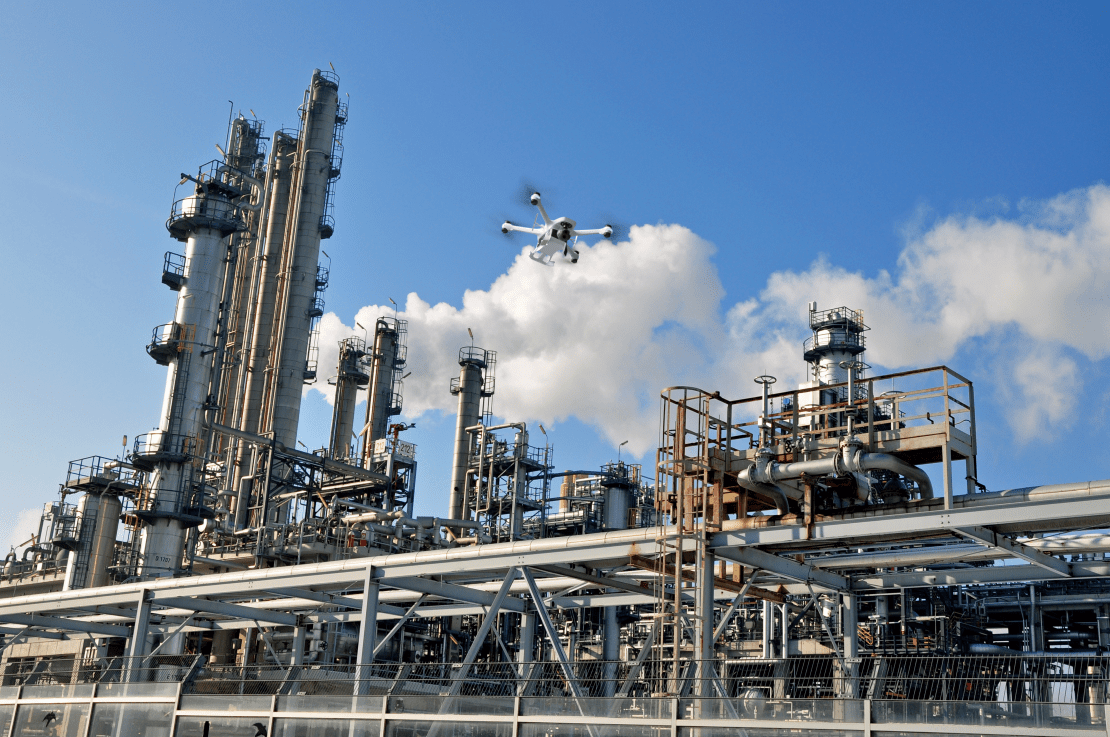

Digitise your inspection processes and access unprecedented levels of information

the optimum inspection operation automation solution.

Detect anomalies before they get worse.

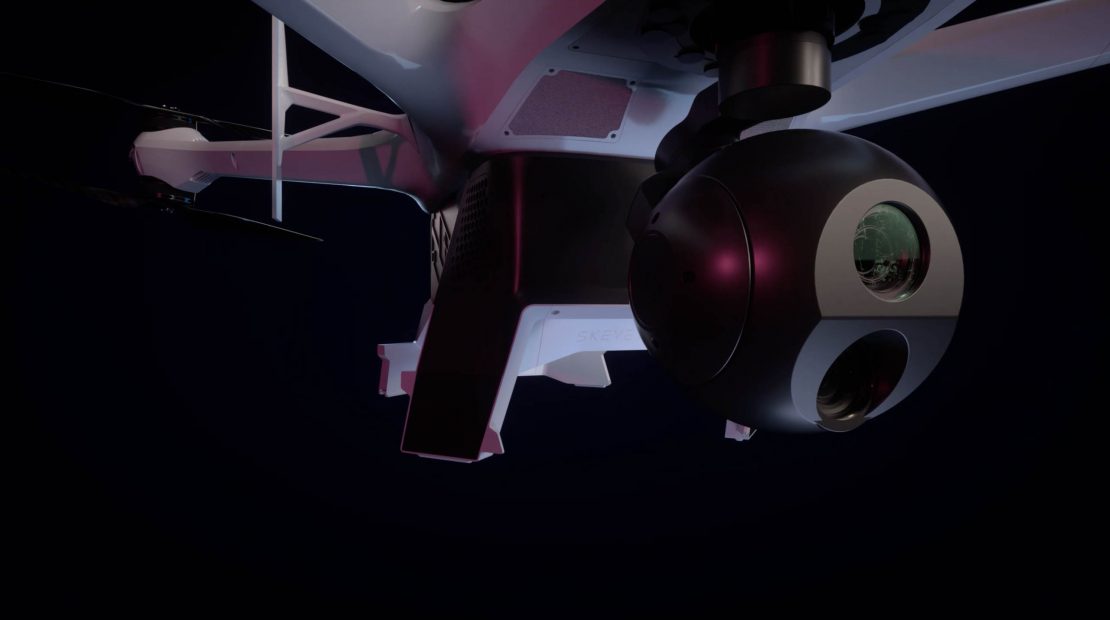

Skeyetech E2 conducts recurrent, quality inspections and contributes to your site digitisation process by collecting large amounts of visual data. Skeyetech E2 allows the creation of digital twins and predictive maintenance models.

AUTOMATE YOUR INSPECTION WORKFLOW USING SKEYETECH E2:

Mission edition

Edit missions to inspect the elements of your site, in particular high-rise structures such as flares, tanks, and all types of high spots.

Mission SCHEDULING

Launch regular and automated inspections.

Autonomous data acquisition

Using high-quality optical or thermal images.

VALUABLE INSIGHT

Using Artificial Intelligence, and digital twins, determination of the vulnerabilities on your sites and infrastructure.

Skeyetech E2, your inspection process ally

Strenghten human safety

- Reduce your personnel’s exposure to the most hazardous work;

- Reduce accident risks, providing air support to ground teams;

- Optimise the assignment of your human resources while protecting them.

Optimize inspection operations

- Put an end to complex, time-consuming and costly operations;

- Reduce manufacturing process downtime;

- Improve your personnel’s efficiency and productivity.

Digitize your site and facilities

- Better monitoring with qualified data to facilitate predictive maintenance and anticipate industrial risks;

- More accurate results based on precise, repetitive and usable data.

Reduce environmental risks

- By detecting leaks early through regular inspections, by qualifying and quantifying potential pollution using state-of-the-art technologies;

- By protecting populations and the environment, through early detection of potential pollution;

- By limiting the use of vehicles or helicopters, which are sources of emissions.

Identify defects in your facilities.

Thanks to its especially powerful optics, Skeyetech E2 makes it possible to inspect and detect potential signs of leaks, cracks, rust, defective welds, corrosion, fouling, calcite anomalies, etc.

The radiometric thermal camera provides an accurate thermal inspection of your facilities to detect hot spots, thermal anomalies, heat losses, etc.

Industrial chimneys

Leaks, weaknesses, obstructions, hot spots

pipes

Leaks, corrosion, rust, heat loss

flares

Structural deterioration, flue cleanliness

Storage tanks & containments

Damage, cracks, leaks

Solar panels

Faulty cells, electric failures, soiling

Conveyor beltS

Hot spots

CANE BRIDGES

Rust, corrosion

Roofs & frontages

Heat loss, cracks